EN

Translate:

EN

EN

Translate:

EN

Fuel Storage Systems in house construction team undertake a variety of fuel facilities installations. Our construction projects are always completed to the highest standards and completed on time including:

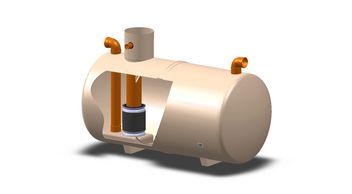

Fuel interceptors can be fitted to surface water drainage systems to protect the environment from pollution by oils. They separate the oil from the water, and then retain the oil safely until it is removed and they have non spark composite manhole covers. They are installed to contain oil leaks from vehicles, storage tanks and accidental spillages. To be effective, oil separators need to be correctly designed, installed and maintained.

Surface water may be contaminated by oil at a number of different sites. These sites need to have measures in place to prevent this oil from polluting the environment. These sites include:

Forecourt separators are full retention specified to retain the maximum spillage likely to occur on a petrol forecourt. They are required for both safety and environmental reasons and will treat spillages occurring during vehicle refuelling and road tanker delivery. The size of the separator is increased in order to retain the possible loss of the contents of one compartment of a road tanker, which may be up to 7,600 litres. A fuel interceptor is a must in most cases for fuel facilities construction.

Fuel Storage Systems can construct reinforced concrete bases to suit any size fuel storage tank or generator set.

Class 1 fuel separators are designed to achieve a concentration of less than 5 mg/l of oil under standard test conditions. These separators are required for discharges to surface water drains and the water environment.

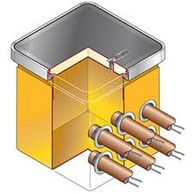

We supply and install water tight electrical draw chambers in a variety of sizes to suit any size installation.

We supply & install heavy duty composite manhole covers in various sizes.

The ACO S range provides excellent hydraulic performance, significantly greater than equivalent 100 mm internal diameter pipes. The ACO S range is an interconnecting heavy duty channel surface water drainage system, that has been designed as the optimum solution to a wide range of Load Class F900 applications.

Nationwide Coverage Including

Accrington - Barnsley - Barrow-in-Furness - Bath - Bedford - Birmingham - Blackpool - Bradford - Brighton & Hove - Bristol - Bolton - Bournemouth - Boston - Cambridge - Canterbury - Carlisle - Chelmsford - Chester - Chichester - Colchester - Coventry - Crewe - Darlington - Derby - Doncaster - Dover - Durham - Eastbourne - Ely - Exeter - Gloucester - Grimsby - Hartlepool - Hastings - Hereford - Huddersfield - Immingham - Ipswich - Isle of Wight - Kidderminster - Kingston-upon-Hull - Lancaster - Leeds - Leicester - Lichfield - Lincoln - Liverpool - London - Luton - Manchester - Middlesborough - Milton Keynes - Newcastle-upon-Tyne - Norwich - Northampton - Nottingham - Oxford - Peterborough - Plymouth - Portsmouth - Preston - Reading - Ripon - Rotherham - Salford - Salisbury - Scarborough - Scunthorpe - Sheffield - Southampton - Southend-on-Sea - St Albans - Stockport - Stoke on Trent - Swindon - Sunderland - Truro - Wakefield - Wells - Westminster - Whitby - Wigan - Winchester - Wolverhampton - Worcester - Yeovil - York

Northern Ireland

Armagh - Bangor - Belfast - Lisburn - Londonderry - Newry

Scotland

Aberdeen - Dundee - Dunfermline - Edinburgh - Glasgow - Inverness - Perth - Stirling

Wales

Bangor - Cardiff - Newport - St Asaph - St Davids - Swansea - Wrexham

Bedfordshire - Berkshire -Buckinghamshire - Cambridgeshire - Cheshire - Cornwall - Cumberland - Derbyshire - Devon -Dorset - Durham - Essex - Gloucestershire - Hampshire -Herefordshire - Hertfordshire - Huntingdonshire - Kent - Lancashire - Leicestershire - Lincolnshire - Middlesex - Norfolk - Northamptonshire -Northumberland - Nottinghamshire - Oxfordshire - Rutland - Shropshire - Somerset - Staffordshire -Suffolk - Surrey - Sussex - Warwickshire - Westmorland - Wiltshire - Worcestershire - Yorkshire

Crown Dependencies

Isle of Man

Douglas

Overseas Territories

Bermuda

Hamilton

Gibraltar

City of Gibraltar

Falkland Islands

Stanley

Saint Helena

Jamestown